Development of Intelligent Charging and Discharging Management System for Electric Vehicles

Development of Intelligent Charging and Discharging Management System for Electric Vehicles

Intelligent charging and discharging management based on EV driving plan, contributing to reducing electricity costs

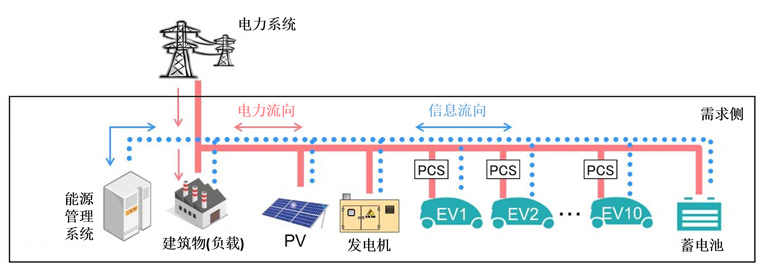

Mitsubishi Electric Corporation has developed an energy management technology that integrates power generation equipment such as electric vehicles (EVs) and solar photovoltaic systems (PV) while parked. With the increasing awareness of environmental protection, this technology will utilize the accelerating popularity of EVs as building batteries, and form a linkage with changes in electricity prices to optimize the charging and discharging schedule of EVs and the operation of PV and generators, achieving the reduction of building electricity costs and the "peak shaving and valley filling" of purchasing electricity from the power system, improving the stability of the power system, reducing fixed investment in power equipment, lowering the cost of electricity demand side use, and contributing to industrial development.

As one of the application forms of this technology, starting from November 2018, Mitsubishi Electric Corporation and Mitsubishi Electric (China) Co., Ltd. jointly imported the system into the factory of Mitsubishi Electric Automotive Parts (China) Co., Ltd. (Changshu, China) for empirical experiments in China, which is expected to achieve the popularization of EVs.

Figure 1 Energy Management System for Flexible Use of Power Generation and Storage Equipment

Development Features

1. By optimizing the EV charging and discharging schedule, the electricity cost of the building has been reduced by 5%

Input the unit price of electricity and the driving plan of EVs, predict the demand for electricity and PV power generation, and optimize the operation plan and charging and discharging schedule of each power generation equipment through a unique mathematical planning method

Multiple electric vehicles (EVs) and photovoltaic (PV) power generation equipment parked in the joint building, using PCS ※ 1 that can charge and discharge EVs, to achieve "peak shaving and valley filling" of purchasing electricity from the power system

・ It has been confirmed through simulation and trial calculation that 10 EVs can be used in the model of one tenth of a 1000 person factory, and the typical demand mode and EV use plan can reduce the power cost by 5%

※1 Power Conditioning System

2. By implementing phased control, even changing the EV's driving schedule can suppress the increase in electricity costs

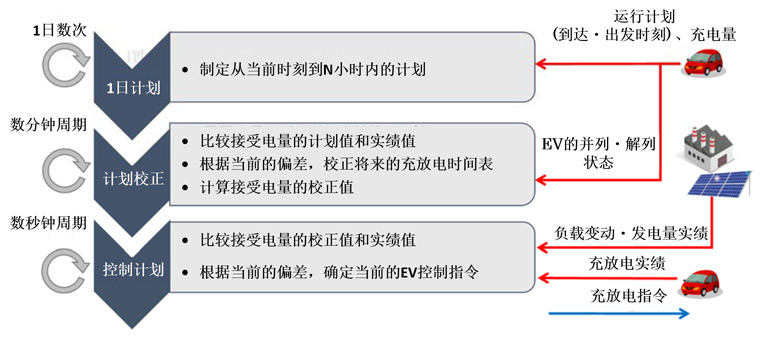

Combine the "1-day plan" (developing a charging and discharging plan multiple times a day within the next 24 hours), "plan revision" (developing a charging and discharging plan with a cycle of minutes within the next few hours), and "control plan" (developing a plan with a cycle of seconds) to monitor the purchased electricity and EV charging volume from the system, and correct deviations between actual performance and charging and discharging plans

Monitor the charging connection and disconnection of EVs that change at any time, and optimize only the EVs in the connected state each time. By developing a detailed charging and discharging schedule, the increase in electricity costs is suppressed

※ 2 Disconnect the EV from the charging and discharging device

Future promotion

In the future, our company will continue to carry out research and development work with the goal of achieving higher efficiency and performance. And integrate with our company's energy management system to further expand our business in the energy sector.

Development background

In Japan, the energy consumption of the industrial sector accounts for approximately 46% of the national energy consumption. In addition, in the context of increasing awareness of global warming, in order to reduce environmental burden, the transportation sector is accelerating the popularization of new energy vehicles represented by EVs. The Chinese government has set a target of achieving 40% of the total sales of new energy vehicles by 2030, with coal-fired power generation accounting for about 70% of the power supply due to high environmental loads. The sales volume of new energy vehicles in 2018 is expected to reach 1 million units. However, with the popularity of new energy vehicles, especially electric vehicles, charging will bring enormous pressure to the power grid system, leading to power shortages and instability, which can easily cause safety issues in the power grid system.

In recent years, energy management technologies have been developed that store power from distributed energy sources in batteries or EVs and discharge it according to electricity demand to reduce peak electricity consumption. This technology helps to improve the utilization rate of renewable energy and its friendliness towards the power grid. Compared with fixed batteries, EVs have higher mobility and stronger charging and discharging performance. At the same time, EVs are an indispensable and important member of the development of smart cities. Energy management technology that uses EVs as both power sources and loads for transmitting and receiving electricity is receiving widespread attention.

In the past, EV energy management technology required EVs to arrive and depart completely according to pre entered scheduled times. Under unplanned driving conditions, EVs became unusable. At this time, even if the electricity cost was high, they had to purchase electricity from the power system.

The EV energy management technology developed by our company this time is designed to flexibly apply EV batteries, which will be widely used as part of building power sources in the future. Even under driving conditions beyond the scheduled schedule, the charging and discharging schedule can be adjusted to minimize electricity costs as much as possible.

Detailed features

1. By optimizing the EV charging and discharging schedule, reduce the electricity cost of buildings by 5%

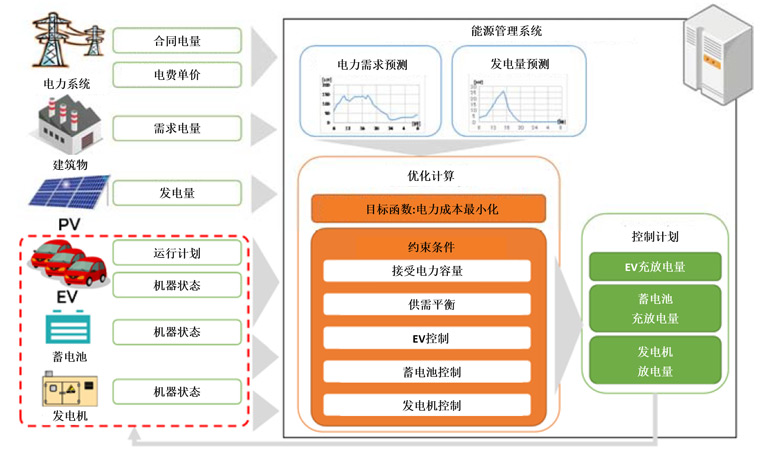

Multiple electric vehicles (EVs) and photovoltaic (PV) power generation devices in the internal parking of the joint building are used to predict the demand for electricity and PV power generation. By optimizing the calculation with minimizing electricity costs as the objective function, peak shaving and valley filling are achieved. When conducting optimization calculations, it is necessary to input the contracted electricity quantity, electricity bill unit price, required electricity quantity, EV driving plan, etc. The contracted electricity quantity is subject to constraints such as power capacity, supply-demand balance, and maximum/minimum charging and discharging capacity of the battery. A unique mathematical planning method is used to develop the operation plan and charging and discharging schedule for each power equipment (Figure 2).

The previous energy management system set a threshold for the required electricity not exceeding the contracted electricity, charged the EV in advance, and controlled the discharge when the required electricity exceeded the threshold. Therefore, if the driving schedule of some EVs suddenly changes, they need to be charged during periods of high electricity bills or during peak hours of the system.

The technology developed this time is based on considering the changes in demand for electricity and electricity prices, and developing a ****** operation plan and EV charging and discharging schedule, in order to discharge the electricity previously charged into the EV in places or/and time periods with lower electricity prices during periods of high electricity prices. In the one tenth model of a 1000 person factory, 10 EVs are used for simulation. After comparison with the situation without energy management, it is found that the power cost can be reduced by 5%.

Figure 2 Schematic diagram of minimizing electricity costs based on energy management system

2. By implementing phased control, even if the usage schedule of EVs is changed, the increase in electricity costs can be suppressed

Combine the "1-day plan" (developing a charging and discharging plan multiple times a day within the next 24 hours), "plan revision" (developing a charging and discharging plan with a cycle of minutes within the next few hours), and "control plan" (developing a plan with a cycle of seconds), while monitoring the purchased electricity and EV charging amount from the system, and correcting the predicted deviation from the charging and discharging plan and the deviation from the EV usage schedule, to improve the accuracy of the driving plan and charging and discharging schedule (Figure 3).

Although previous energy management systems would adjust the plan when the deviation from the daily forecast of PV generation and demand increased, the failure to consider EV arrival delays and insufficient energy storage upon arrival resulted in the inability to achieve peak shaving, making the increase in electricity costs an urgent issue to be addressed.

Because the technology developed this time monitors the charging connection and disconnection status of EVs, and only optimizes (i.e. minimizes power costs) the EVs in the connection status each time, correcting the charging and discharging schedule every few minutes. Therefore, by refining the charging and discharging schedule, even if there are situations that differ from the plan, the increase in power costs can be suppressed.

Figure 3 Schematic diagram of plan revision method

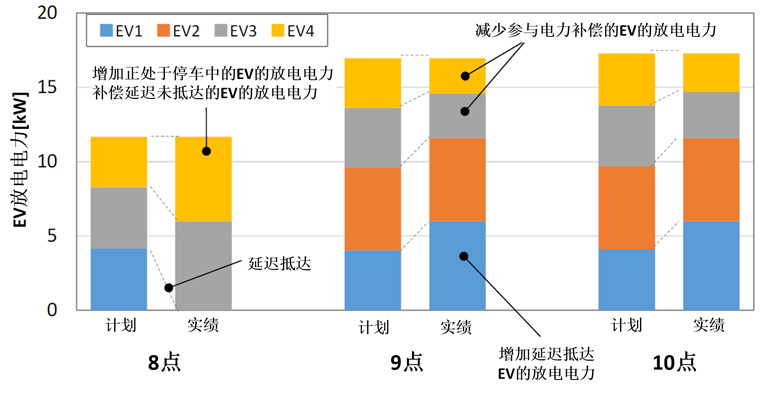

For example, as shown in Figure 4, if EV1, which was scheduled to arrive at 8 o'clock, experiences a delay and actually arrives at 9 o'clock, it will not be possible to discharge from EV1 between 8 and 9 o'clock. Due to the high electricity cost from 8pm to 12pm, in order to avoid increasing the electricity purchased from the system, it is necessary to increase the discharge power of EV3 and EV4 that are currently parked from 8pm to 9pm. After EV1 arrives at 9 o'clock, the discharge power of EV1 can be increased to reduce the discharge power of EV3 and EV4, thereby suppressing the increase in electricity costs. Even if the driving plan of EVs changes, it can be suppressed by changing the proportion of discharge of each EV at different time periods.

Example of Correction for Charging and Discharging Schedule in Figure 4

Summary of Chinese Domestic Empirical Experimental Related Companies

| Company name | location | Main business content |

|---|---|---|

| Mitsubishi Electric (China) Co., Ltd | China (Beijing) | Regional consolidation and investment and financing, various consulting, and research and development support to regional bases |

| Mitsubishi Electric Automotive Parts (China) Co., Ltd | China (Changshu) | Manufacturing, sales, and technical support of automotive machinery (electrical equipment, electric power steering system products for automobiles, multimedia products for automobiles). |

patent

6 Japanese patents and 3 patents from other countries

Technical Development Manager

Mitsubishi Electric Corporation Advanced Technology Research Institute

1-1, Nakaguchi Honcho, Nishizaki City, Hyogo Prefecture, Japan 661-8661

FAX:(0081)06-6497-7289